Share

Over the last 50 years, essential technology that a machine shop should have has dramatically changed. Gone are the days of having just a manual milling machine, manual lathe and a drill press. If you want to do production and be competitive, the old equipment and ways are not going to help you. CNC-powered equipment took over in the 1980s and 1990s, but in order to be more competitive these days, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools. There are so many more essential tools that a machine shop needs in its arsenal.

Here are six essential tools that should be in your machine shop:

- Multitasking lathes and five-axis machining centers. The five-axis machining center has become the standard when purchasing a new machining center. Some companies are intimidated by these machines, but they are far easier to set up then a horizontal machining center. Most companies feel they are harder to program. I agree if you are doing full five-axis programming but most companies use them for five-axis positioning, which is much easier. Multitasking lathes are intimidating as well, but they can be programmed with CAM systems much easier than they used to be. These five-axis machines, along with multitasking lathes, will enable a machine shop to get the job done faster and more accurately since they can do many more tasks than with conventional CNC equipment. Parts come out more complete and with less errors — an essential outcome to keep up in the current industry.

- Robots and automation. Automation technology is essential for staying competitive. Skilled labor is hard to find and we need to make our current employees more productive by taking away repetitive work like loading and unloading machines. Robots and automation contribute greatly to a shop’s consistency, which leads to increases in productivity and quality.

- Coordinate measuring machines (CMMs). It is now essential that shops have a CMM. These machines take care of difficult measurements. I cannot imagine how companies made such measurements many years ago! The CMM is essential to accurate, consistent and timely measurement of parts. They also enable measurements to be automatically documented so that you can provide the necessary data if required to provide proof of measurement.

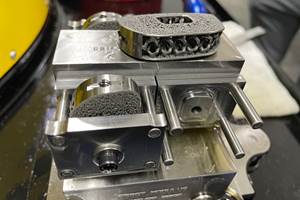

- 3D printing. 3D printing has been around for years and it has been great for prototyping and other uses. I also see it used a lot more for making fixtures for holding parts. There are uses being created every day. I do not know if it will replace machining since every advancement in 3D printing is being done at the the same time as advancements in machining, and therefore there would need to be some huge technical leaps for it to take over. I do consider 3D printing essential in a machine shop as a tool to help get jobs done.

- 3D scanning. This tool complements 3D printing, but it can be used for so many other things. I believe that 3D scanning will eventually challenge CMMs in the quality control departments of a machine shop, as 3D scanning is a more complete way of measuring a part. The big issue with CMMs is that they do not normally measure all the features of a part. 3D scanning is more holistic in measuring a complete part, and it can better point out differences. This is essential because often it is the “unimportant” areas that can go out of tolerance when you are not careful. 3D scanning is also an essential tool for reverse engineering of parts. The 3D scanner is becoming more essential every day, and not having one will really limit your machine shop.

- Enterprise resource planning (ERP) systems. ERP systems are becoming more and more essential to having a competitive machine shop. I have seen too many shops use spreadsheets to schedule. This is very time consuming since you essentially have to manually update everything for many entries. ERP systems can manage your workflows so much better. They can manage scheduling jobs, material and services at the same time. They can help give management and employees greater visibility in seeing where jobs are and how well they are running. I think that future ERP systems will tie themselves closer to monitoring machines on an active basis to address manufacturing issues as well as maintenance issues. ERP systems are now essential to managing your machine shop!

The days running a competitive machine shop with just a few manual machines are long gone. If your shop doesn’t have the six essential tools that are listed above, then you will find that you are not going to be as competitive as the shops that do have them. They are essential to running a machine shop that is competitive with the current state of the industry and will continue to serve your shop as the industry evolves.

Related Content

An Additive Manufacturing Machine Shop

Finish machining additively manufactured implants requires different pacing and workflow than cutting parts from stock — different enough for an experienced manufacturer to warrant a dedicated machine shop.

Read MoreHigh RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

Read More10 Ways Additive Manufacturing and Machining Go Together and Affect One Another

Forget “additive versus subtractive.” Machining and metal additive manufacturing are interconnected, and enhance the possibilities for one another. Here is a look at just some of the ways additive and machining interrelate right now.

Read MoreAdditive/Subtractive Hybrid CNC Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreRead Next

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreIMTS 2024: Trends & Takeaways From the Modern Machine Shop Editorial Team

The Modern Machine Shop editorial team highlights their takeaways from IMTS 2024 in a video recap.

Read MoreInside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

Read More

.jpg;maxWidth=300;quality=90)