Bloodhound Fin Support Machined with Vortex

Machining strategy contributes to 40 percent cycle time saving on large five-axis aluminum part.

Five-axis machining may be challenging, but it’s not rocket science. Except when it is.

The Bloodhound is a 1,000-mile-per-hour rocket-powered car being developed to break the world land speed record, possibly this year. Though it’s named for a surface-to-air missile, the Bloodhound car will maintain missile-like speed entirely on the surface.

We’ve reported before on a leading-edge part made for this car. News of one of the latest examples of an unusual part for this car come from Delcam, whose PowerMill software and Vortex machining strategy figured into the five-axis machining of a tail-fin shear plate that will support the car’s large vertical fin at full speed.

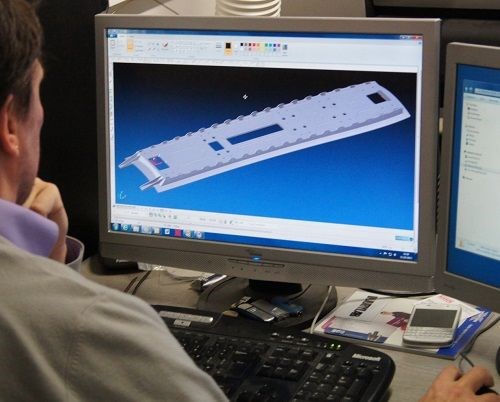

The part shown on the screen in the previous image supports the car’s large vertical fin against the drag at full speed. Find images of the completed machined part posted here.

According to this BBC report, the aluminum plate—machined by Manufax Engineering on a Correa five-axis gantry-type—is more than 2 meters long by 400 mm wide, but only 2 mm thick in some places, and precisely curved to follow the contour of the chassis. An aluminum block weighing 750 kg was milled down to less than 9 kg to make this part.

Delcam says the combination of tooling from SGS and tool paths achieving efficient engagement through Vortex allowed the part to be machined with over 40 percent less cycle time than it would have otherwise required.

Related Content

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

-

Can ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

.jpg;maxWidth=300;quality=90)