Industrial Fiber Laser Solutions for Marking and Traceability

IMTS22: Dapra’s latest industrial-grade fiber laser marking and engraving technology provides reliable performance, fast cycle times and outstanding flexibility to fit any manufacturing environment.

The latest industrial-grade fiber laser marking and engraving technology provides reliable performance, fast cycle times and outstanding flexibility to fit any manufacturing environment — from standalone workstations to production line integration.

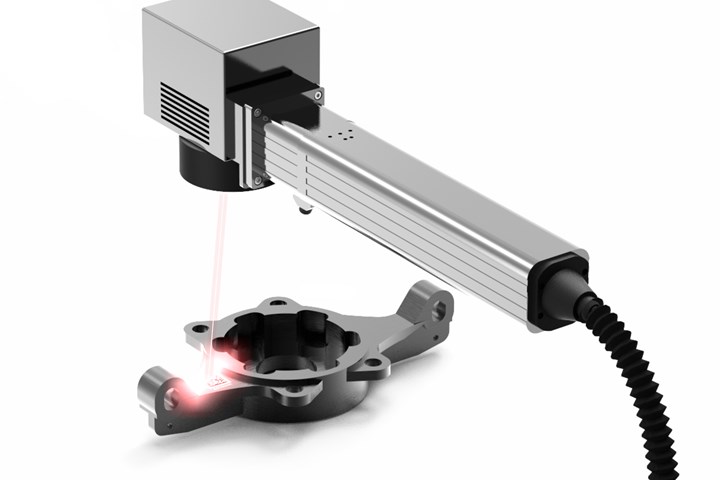

Datamark FL Series laser markers from Dapra Marking Solutions offer precise, repeatable, non-contact marking of metals, alloys and most plastics. Available with Q-switched and MOPA-fiber laser sources from 20 to 50 watts, these systems are said to be capable of everything from high-contrast annealed heat marks with no surface disruption to the crisp engraving of both basic text and complex patterns at depths exceeding .004".

FL Series markers can be mounted in open Class 4 workstations or Class 1 safety enclosures, with a programmable Z-axis, optional rotary D-axis and integrated barcode reading and verifying technology. Dapra says they are designed for easy integration into robotic cells, production lines and other highly engineered solutions to support modern manufacturing environments.

Every system ships with the Datasoft Pro Windows software suite, supporting easy logo import, serialization, date coding, Data Matrix and QR codes, UID and UDI syntax and much more. With an icon-based, WYSIWYG interface, the software puts all the tools to meet challenging marking requirements.

Dapra says it has supported North American manufacturers’ unique marking and traceability requirements for nearly 40 years.

Related Content

-

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

-

CNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

-

An Additive Manufacturing Machine Shop

Finish machining additively manufactured implants requires different pacing and workflow than cutting parts from stock — different enough for an experienced manufacturer to warrant a dedicated machine shop.