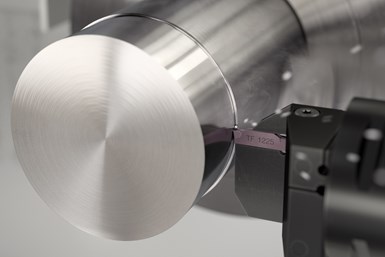

Sandvik Coromant Grooving Tool Provides Stable Performance

The CoroCut 2 system features an improved clamping finger design, which offers a higher clamping force and better side stability.

Share

Sandvik Coromant is upgrading its CoroCut 1-2 parting and grooving concept to provide improved stability, greater flexibility and significant productivity gains with the new CoroCut 2 system.

Stability is key when working with all parting and grooving operations. The main challenge is keeping the insert in place to minimize all forms of insert movement. The rail interface, previously available on medium and large inserts, offers more precise insert positioning and makes the insert resilient to any lateral forces exerted on it. This rail interface will now also be available on smaller insert sizes, providing stability in all operations.

CoroCut 2 parting blades are upgraded with internal coolant and an improved clamping finger design, which offers a higher clamping force and better side stability. Toolholders with precision coolant are updated with a screw clamp solution, which — combined with the rigid rail insert seat design — keeps insert movement to a minimum without any loss of clamping force.

Other important features included in the upgrade are new and updated grades and geometries, including the new first choice grade GC1225, a wiper design for all parting geometries and greatly enhanced edge line quality on all inserts.

CoroCut 2 can be used in all types of parting and grooving applications with cutting depths suitable for double-edged inserts. The related CoroCut QD and CoroCut QF concepts are recommended for larger depths of cut, while CoroCut QI is the specialized for internal grooving and face grooving on small diameters.

Related Content

-

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

-

High-Feed Machining Dominates Cutting Tool Event

At its New Product Rollout, Ingersoll showcased a number of options for high-feed machining, demonstrating the strategy’s growing footprint in the industry.

-

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.