Testing Measures Impact of Toolholder Interface Rigidity

Though Big-Plus and HSK share superficial similarities, they differ fundamentally in how they clamp the holder--a difference with important implications.

Big-Plus and HSK are superficially similar in some ways. Both of these machining center spindle-and-toolholder interface systems aim to provide a more stable connection than the typical machining center system employing standard conical toolholders. And both of these systems are roughly equal in price when it comes to purchasing a set of toolholders for a machine. But Cory Cetkovic, applications engineer for Big Kaiser Precision Tool, says the two interface systems actually differ fundamentally in their method of clamping the holder. That difference has important implications.

The Big-Plus system involves elastic deformation of the spindle connection, he says. During clamping, that deformation results in axial displacement of the toolholder into the spindle. Prior to clamping, the toolholder makes only taper contact within the spindle, but after clamping of the retention system, the spindle expands within an elastic limit until the toolholder achieves the second area of contact—contact at the spindle face—that is the defining feature of the Big-Plus system.

HSK, meanwhile, works by elastically deforming the toolholder. Fingers inside the hollow shank of the toolholder clamp the holder by pushing out. High spindle speed helps this interface, because the centrifugal force strengthens this clamping.

In large part because of this very different clamping, these two systems are not equivalent, says Mr. Cetkovic. Big Kaiser supplies hardware for both, including Big-Plus tooling manufactured by Big Daishowa Seiki, the originator of the concept, and HSK toolholders that are hard milled, hard turned and ground after heat treatment for precision, surpassing that of commodity holders. Thus, the company often advises shops considering new machine tools on which toolholder interface to select. The choice depends on the application, he says. It also depends partly on the wishes of the user.

For example, the notion that a set of toolholders for either system is roughly equal in price, while outwardly true, masks a source of savings with Big-Plus that might be important to a given shop. Big-Plus is the system that adds spindle face contact for heightened rigidity to a toolholder interface that otherwise uses the same 7:24 cone of CAT and BT tapers. As a result, standard CAT and BT holders can be used in a Big-Plus machining center, and Big-Plus holders can be used in standard machines. Though the face contact is not realized in either of these cases, a given shop might prefer the Big-Plus system’s freedom to use existing, standard holders in cuts for which the rigidity doesn’t matter.

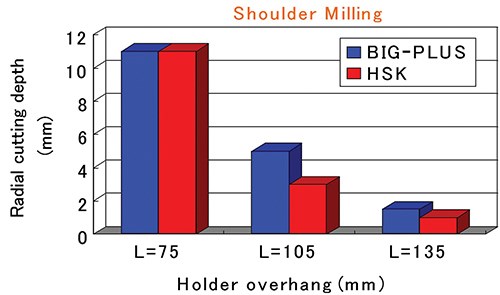

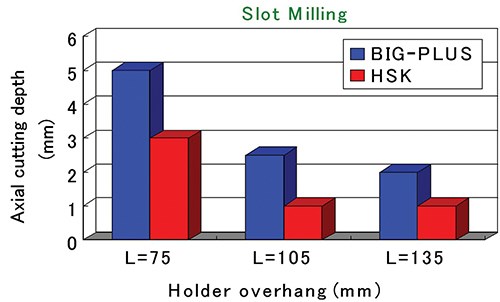

Testing at Big Kaiser has measured what this rigidity means and what performance it seems to delivers within the range of applications most favorable for this system. Machining tests with a 12-mm four-flute carbide end mill were run on two identical machines (same make and model), one equipped with Big-Plus and the other with HSK. On each machine, the workpiece was milled at various tool overhang lengths to measure the maximum axial and radial depths of cut at which the tool would perform effectively. The graphs on this page show the depths of cut at which chatter set in for each set of parameters. No doubt the different natural frequencies of the different toolholder systems contributed to how deeply a given tool setup could cut without chatter, so clamping stiffness alone isn’t the whole story. Still, at nearly every test run, the Big-Plus system provided for the capacity to take a deeper cut.

But results such as these do have a speed limit, Mr. Cetkovic says. It is the shops moving into higher spindle speeds that ought to consider HSK, partly because of the toolholder’s lighter mass, and partly also because of the very fact that the toolholder in the HSK system deforms rather than the spindle. Again, high rotational speed helps the clamping of this interface.

At around 24,000 rpm, he says, the centrifugal force’s relaxation of the connection for a conical holder, combined with that same force’s strengthening of the HSK clamp, results in the rigidity advantage crossing over to favor HSK from that speed up.

Related Content

Lyndex-Nikken Toolholders Offer Stable, Versatile Machining

Polygonal shank toolholders provide a rigid connection between the tool and machine — ideal for all processes both in turning and milling.

Read MoreTungaloy Grooving Toolholders Provide Highly Stable Machining

TungHeavyGroove includes an enhanced insert clamping design for maximum tool rigidity.

Read MoreCeratizit's Updated Tooling Solutions Improve Machining Performance

The company has upgraded its EcoCut indexable inserts lineup, as well as introduced two new toolholding and workholding solutions.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreRead Next

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreInside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

Read MoreIncreasing Productivity with Digitalization and AI

Job shops are implementing automation and digitalization into workflows to eliminate set up time and increase repeatability in production.

Read More

(4).png;maxWidth=300;quality=90)