What Your Handbook Isn’t Telling You

Tony Schmitz, professor at the University of North Carolina at Charlotte, gives a presentation on machine tool dynamics. Learn the role that this concept plays in realizing your optimal machining center performance.

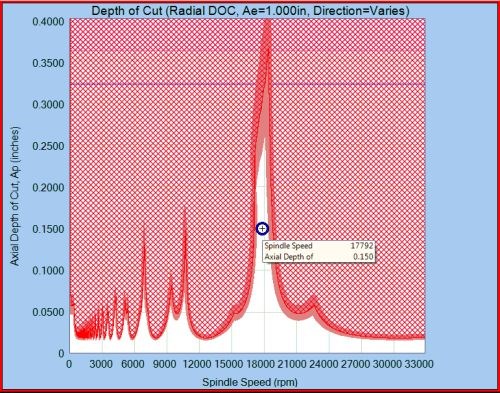

This example of a stability diagram shows how increased depths of cut that are possible within specific, narrow bands of spindle speed. Sometimes a deeper cut is possible at a higher speed than where the process is currently running.

— The best-performing speeds for a given machining process often do not correspond to machining handbook values.

— Your process might actually deliver better tool life, surface finish and/or metal removal rate if you increase the speed rather than reduce it.

After watching Dr. Schmitz’s presentation, see an example of turning up the speed in this video, and read about how one shop is applying this phenomenon to realize the most efficient performance from its own machine tools.

Related Content

-

The Benefits of In-House Toolmaking

The addition of two larger gantry routers has enabled a maker of rubber belting products to produce more tooling in-house, reducing lead times and costs for itself and its sister facilities.

-

10 Ways Additive Manufacturing and Machining Go Together and Affect One Another

Forget “additive versus subtractive.” Machining and metal additive manufacturing are interconnected, and enhance the possibilities for one another. Here is a look at just some of the ways additive and machining interrelate right now.

-

DN Solutions' VMC Provides Diverse Five-Axis Machining

The company’s DVF Series comprises compact five-axis CNC machines that are designed for diverse five-sided or simultaneous five-axis applications.